While technological advances have changed the life and behaviours of health-conscious people, who can take better care of themselves with the help of smart devices, they have also hugely benefitted the medical sector.

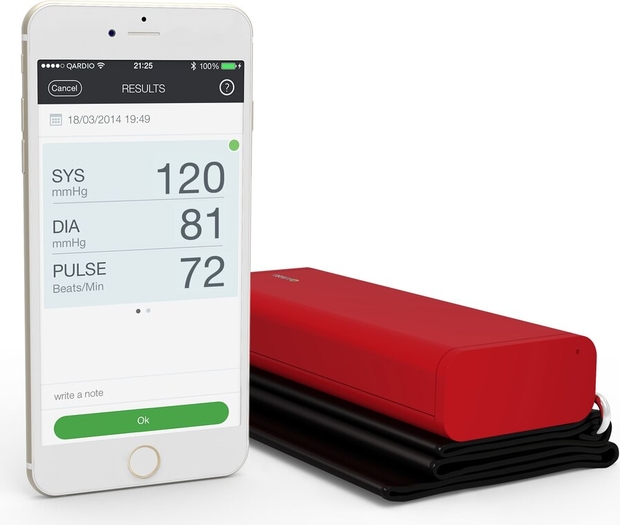

In a not so distant past, a doctor appointment – or at least a visit to a chemist – was necessary to have one’s blood pressure measured. The advent of electronic devices in the second half of the 20th century changed behaviours, allowing people to monitor it at home. The same goes for blood sugar levels: electronic home glucose meters were on the market in the early 1980s, allowing people with diabetes to check the concentration of glucose in their blood several times a day.

Heavier treatments, such as dialyses, can now also be performed at home. While in the past patients had to block time and go to a specialized facility to receive therapy, they can now use home dialysis equipment, thus reducing the costs of therapy and increasing their personal comfort.These technological innovations and advances wouldn’t have been possible without sensors. They have played a major role in the development of the sophisticated and extremely accurate equipment installed in medical centres, and are obviously key in the in-home and wearable devices that are increasingly used by patients throughout the world.

Sensors come in many shapes and forms: vision, flow, fibre optic, gas, motion, image, colour, light, pressure, infrared, photoelectric and so on. They are a key underpinning technology for a wide range of applications. In medical equipment for instance, pressure, temperature and force sensors monitor critical parameters in dialysis equipment. For fall and activity tracking, sensitive pressure sensors can identify small changes in altitude and differentiate between vertical and horizontal positions or count the number of steps in a given day. Bedridden patient monitoring for activity, respiration and movement is done using piezo film sensing technology.

Sensor technology is advancing rapidly meaning that further intelligence can be integrated into medical devices, making them more sophisticated and at the same time more user-friendly.Even more so than in other sectors, the sensors used in medical equipment need to be extremely high-quality, reliable and accurate. Defective components are not an option since people’s lives are at stake. Sensor manufacturers and suppliers all over the world have a powerful tool at their disposal, enabling their products to meet the strictest requirements: IECQ testing and certification. IECQ, the IEC Quality Assessment System for Electronic Components was established in the early 1970s. The System has grown with, and adapted to the technological developments in the electronics industry.

In addition, there is a multitude of related materials and processes that are covered by the IECQ Schemes. IECQ certificates are used worldwide as a tool to monitor and control the manufacturing supply chain, thus helping to reduce costs and time to market, and eliminating the need for multiple re-assessments of suppliers.

IECQ operates industry specific Certification Schemes:

- IECQ AP (Approved process)

- IECQ AP-CAP (Counterfeit avoidance programme)

- IECQ AC (Approved component)

- IECQ AC-AQP (Automotive qualification programme) IECQ Scheme for LED Lighting (LED components, assemblies and systems)

- IECQ AC-TC (Technology certification)

- IECQ Avionics – IECQ ADHP (Aerospace, defense, and high performance)

- IECQ HSPM (Hazardous substances process management)

- IECQ ITL (Independent testing laboratory)

In brief, IECQ is an essential player and a key partner of industry in the development of safe, reliable and accurate medical devices and equipment

For more information on IECQ: www.iecq.orgContact IEC

Contact BPS – The Philippines’ member to IEC